插闆(pǎn)式鎖風(fēng)卸灰閥(fa)是根據(ju)我公司(sī)多年生(sheng)産經驗(yan)和客戶(hù)實際工(gōng)況研制(zhi)開發的(de)新型鎖(suǒ)風卸灰(huī)系列。可(kě)廣泛應(ying)用于👣建(jiàn)材🔞、冶金(jīn)🛀🏻、礦山、電(diàn)力、化工(gōng)、糧食、玻(bō)璃等行(hang)業的物(wù)料輸送(song)系統中(zhong)和㊙️作為(wéi)各種磨(mo)機、烘幹(gan)機、料倉(cāng)等的鎖(suo)氣卸灰(hui)裝置。

The valve is the new type of air-locking discharging on the base of the operation experience and the practical working condition of user. It is widely used in building material, metallurgy, mining, electric power, chemical, food and glass industries etc to transport material and to be the air-locking discharge device in dry machine, storage and grinding machine etc.

結(jie)構特點(diǎn):

Structure characteristic:

插闆式(shì)鎖風卸(xie)灰閥采(cǎi)用優質(zhi)碳鋼焊(hàn)接成形(xíng),結構新(xīn)穎、緊湊(còu)、科學。内(nèi)外雙層(céng)結構,避(bì)免粘連(lian)性物料(liao)附着體(tǐ)筒無法(fa)保證鎖(suǒ)氣和運(yùn)行等現(xiàn)象;上下(xià)層結構(gou)可使閥(fá)闆間歇(xiē)交替運(yun)動,保證(zheng)鎖氣功(gong)能。配置(zhi)不同要(yào)求的傳(chuán)動裝置(zhì),可保證(zheng)運行平(píng)穩,卸灰(huī)、鎖氣可(ke)靠。

S為手(shǒu)動式,D為(wéi)電動式(shi),Q為氣動(dong)式,Y為電(dian)液動式(shì);Ⅰ型為圓(yuán)法蘭連(lián)🈲接,Ⅱ型為(wei)方法蘭(lan)連接。

The valve is welded in fine carbon steel, having the features of novel and compact structure and double layers, which can prevent the sticky material from adhering to the cylinder and ensure the normal air locking and operation. The disc can move intermittent alternately because of the upper and lower layer structure. Operation is calm and discharging and air-locking is reliable when it is equipped with different transmission devices.

S denotes manual, D denotes electric, Q denotes pneumatic, Y denotes electric hydraulic; type Ⅰ is the round flange connection and type Ⅱ is square flange connection.

性(xing)能參數(shu):

Performance parameter::

公(gōng)稱壓力(lì) Nominal pressure | 工(gōng)作溫度(du) Working temperature | 洩(xie)漏率 Leakage ratio | 适用(yong)介質 Suitable medium |

0.05MPa | ≤300℃ | ≤0.05% | 粉塵(chén)、顆粒晶(jing)體、微帶(dài)粘性物(wù)料等 Powder with dust, grain crystal and material with small glutinosity |

工(gong)作原理(li):

Working principle:

插闆式(shi)鎖風卸(xie)灰閥主(zhǔ)要由本(běn)體、閥闆(pan)、傳動軸(zhóu)、密封副(fù)及傳⛱️動(dòng)裝👣置等(deng)組成。物(wù)料由進(jìn)料口進(jìn)入 ,落入(ru)料鬥中(zhōng),待工況(kuàng)需要卸(xiè)🤞灰時,人(ren)工向外(wai)拉閥闆(pǎn)手柄即(ji)可卸料(liào),待第一(yī)層料卸(xie)完時,向(xiàng)内推閥(fa)闆手柄(bing),此時,閥(fa)闆象鍘(zhá)刀一樣(yàng),使粘連(lián)在内套(tao)體壁上(shang)的物料(liào)被✉️切斷(duàn),至使閥(fa)闆完全(quan)關閉,重(zhòng)複上述(shù)操作,開(kai)啟下閥(fá)闆,卸灰(hui)、鎖風。配(pèi)🈚置電動(dong)推杆、電(dian)液動推(tui)杆,可實(shi)現自動(dòng)化操作(zuo),推杆在(zài)得到指(zhǐ)✏️令後,通(tōng)電帶動(dòng)閥闆向(xiàng)外位移(yi);滿足卸(xiè)灰需要(yao)後,又向(xiàng)内位移(yí),滿足鎖(suǒ)風需要(yào),下層重(zhong)複上述(shù)操作,形(xing)成整套(tào)完整動(dong)作。配置(zhì)氣動推(tuī)杆,通過(guò)雙控二(èr)🌈位五通(tong)電控換(huàn)向閥驅(qu)動氣動(dong)推杆帶(dai)動閥闆(pan)作往複(fu)運動,完(wán)成整套(tào)卸灰鎖(suǒ)氣動作(zuo)。所有配(pei)置均帶(dài)有行程(chéng)限位裝(zhuang)🐪置,開、關(guān)到位能(neng)反饋指(zhi)示信号(hao)。

The valve is mainly made up of body, disc, transmission shaft, sealing pairs and transmission device etc. The material gets into from feeding intake and fall into the hopper. Pull the handle outwards and discharge. Pull handle inward when discharging of the first layer is over, and the material is cut off, the disc is fully closed. Repeat the above step, open the disc and then discharge and lock air. Automation control can be realized when it is equipped with electric or electric hydraulic draw stem. The stem is powered and drives the disc move outwards after it receives command. It drives the disc move inwards and locks air after discharging. The lower layer repeats the above steps. The double-control two-bit five-way electric-control reversal valve drives the pneumatic draw stem to move with disc. All devices are equipped with stroke limit device and indicating signal can be feed back.

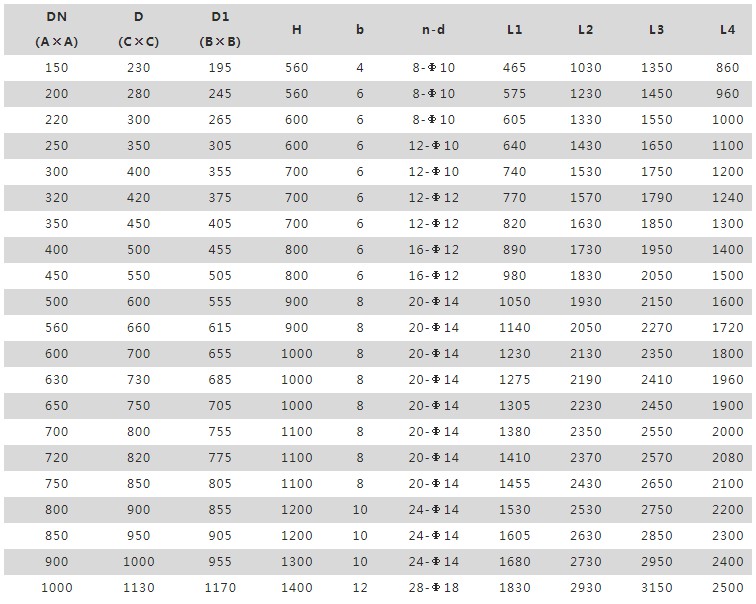

CHF系列 外(wài)形連接(jie)尺寸:

Appearance joint dimension:

傳(chuán)動裝置(zhì)參數:

Transmission device parameter:

規格(gé) Type | 150~250 | 300~560 | 600~850 | 900~1000 |

電(diàn)動推杆(gan) Electric draw stem | DTⅠA63-M P:0.06KW | DTⅠA100-M P:0.25KW | DTAⅡ250-M P:0.37KW | DTⅡA500-M P:0.37KW |

氣動推(tui)杆 Pneumatic draw stem | 10A-5TC50B | 10A-5TC63B | 10A-5TC80B | 10A-5TC100B |

電液推(tui)杆 Electric hydraulic | DYT100 P:0.37KW | DYT300 P:0.37KW | ||

安(ān)裝及調(diao)試:

Installation and regulation

l 安裝(zhuāng)時傳動(dong)裝置不(bú)允許作(zuo)起吊用(yong),并嚴禁(jin)損傷。

l 安(an)裝前必(bi)須清潔(jie)閥門内(nei)腔,不允(yun)許有任(rèn)何雜物(wù)和污垢(gou)附着。

l 安(an)裝前先(xiān)檢查閥(fá)門各傳(chuan)動部分(fen)是否完(wán)好,按用(yong)戶♻️工作(zuò)系統要(yào)求對閥(fa)門做适(shì)當的調(diào)整(出廠(chang)時已作(zuò)标準調(diao)整),試運(yun)行無㊙️誤(wù)後将閥(fá)門處于(yú)關閉狀(zhuang)态再進(jìn)行安裝(zhuāng)。

l 法蘭連(lian)接時加(jia)密封墊(nian)後均勻(yún)鎖緊聯(lián)接螺栓(shuān)。

l The transmission device cannot be hoisted and avoid being damaged when installed.

l The body must be cleaned before installed and there is no dirt and sundries clinging to the body

l Check the transmission part before install. Adjust valve properly according to the demand of user. Close the valve and install the valve after there is no mistake.

l Installation of flange connecting valve is on diagram. Lock down the connecting bolt after add sealing washer.

運輸及(jí)保管:

Transportation and protection

l 運(yun)輸時應(yīng)避免撞(zhuang)擊閥門(mén),閥門應(yīng)處于關(guān)閉位置(zhì)以🚩防在(zai)運輸中(zhōng)閥闆和(hé)傳動部(bu)件損壞(huài)。

l 當閥門(men)運輸時(shi)傳動裝(zhuāng)置及傳(chuan)動部位(wèi)應懸空(kong),以防止(zhǐ)傳動軸(zhóu)🔆受力過(guò)大變形(xing)損壞。

l 傳(chuan)動裝置(zhì)及傳動(dong)部位應(yīng)作防潮(chao)、防雨處(chu)理。

l 該閥(fá)應存放(fang)在幹燥(zào)的室内(nei),不允許(xu)露天存(cún)放或堆(dui)置🍓。長期(qī)🏃♂️存放📐時(shí)應使閥(fá)門處于(yú)關閉狀(zhuang)态,各傳(chuan)動部📞位(wèi)加潤滑(huá)📱油,傳動(dòng)裝置作(zuo)防潮、防(fáng)塵處理(lǐ)。

l Avoid bumping and the valve is in full close in order to avoid damage of disc and driving part.

l Transmission device and part should be hung up when the valve is transported in order to prevent damage of axle.

l Treatment of dampproof and rainproof should be done to transmission device and part.

l The valve should be stored in dry room and should not be piled up in open air. It should be in full close state when long stored. Add lubrication to the transmission part and the device should be dampproof and dustproof.

維護及(jí)檢修:

Maintenance and examination

l 定(ding)期檢查(cha)各傳動(dong)部位的(de)運行情(qing)況。

l 定期(qī)更換電(diàn)動推杆(gan)的潤滑(hua)脂以保(bao)證其機(ji)械部分(fen)不🏒受損(sǔn)壞。

l 定期(qī)檢查閥(fá)門轉軸(zhóu)處的密(mì)封狀況(kuang),如發現(xian)密封問(wen)題請😍更(geng)換♉或填(tián)加石墨(mò)填料。

l Check the operation condition of transmission part regularly.

l Exchange the lubricating grease of electric draw stem regularly to avoid damage of machinery part.

l Check the seal condition of rotating axle regularly and exchange or fill with graphite filler.

訂(dìng)貨須知(zhi):

Information for order

l 選用訂(ding)貨時,請(qǐng)參照産(chǎn)品樣本(ben)注明産(chan)品規格(ge)、型号及(ji)技術參(can)數(使用(yong)溫度、設(shè)備工況(kuàng)、介質性(xing)質等)。

l 樣(yàng)本所示(shi)産品圖(tú)例及表(biao)格中所(suo)列傳動(dòng)裝置号(hào)為我公(gong)司普通(tong)基本配(pèi)置,不帶(dài)任何相(xiang)關配件(jian)。您若有(yǒu)特殊要(yào)求(防爆(bào)、戶外😘),請(qing)在💛合同(tóng)中注明(míng)。

l 表格中(zhong)未列規(guī)格、用于(yú)特殊介(jie)質或其(qi)它特殊(shū)要求,請(qǐng)與我公(gong)司經銷(xiao)部、技術(shu)部聯系(xi),可為您(nin)另行設(shè)計、制造(zao)。

l Please indicate the type, model and technical parameter (using temperature, working condition of equipment and characteristic of medium etc) referring to the product sample when you place an order.

l Product legend in the sample and electric device listed in table is the basic normal collocation of our company without any corresponding accessory. If you have especial demand (anti-explosion, outdoors etc), please indicate it in the contract.

l If you have other special demand, need special medium or the spec that is not listed in the table, please contact with our department of market and technology. We can design and manufacture for you especially.

湖(hú)北大庆(qing)万美塑(sù)料制造(zao)有限公(gōng)司(5G网站(zhan)) 版權所(suǒ)有 荊州(zhōu)百捷 技(jì)術支持(chi)

地址:荊(jing)州市沙(shā)市區十(shi)号路 咨(zī)詢熱線(xian):0716-8878286